So, you're here because you want to dive deep into the world of truss and beam, right? Whether you're a DIY enthusiast, an aspiring architect, or just someone curious about how buildings stand tall and strong, this article’s got you covered. Truss and beam systems play a crucial role in construction, acting as the backbone of structures that we see every day. From houses to bridges, these components ensure stability and durability, making them indispensable in the world of architecture and engineering.

Now, before we get into all the nitty-gritty details, let me tell you something interesting. Did you know that trusses and beams have been around for centuries? Yep, they’ve been holding up buildings since way back when people first started constructing stuff that needed to last. Understanding how they work can give you a whole new appreciation for the engineering behind the buildings we take for granted.

But here’s the deal – knowing about truss and beam isn’t just about admiration. It’s practical knowledge that could save you money, time, and headaches if you’re planning any kind of construction project. So, buckle up, and let’s explore everything you need to know about truss and beam systems. Whether you're building a shed or designing a skyscraper, this guide will be your go-to resource.

Read also:Viral Coach Wallet Why Everyones Talking About It And Why You Should Care

What Exactly Are Truss and Beam?

Alright, let’s start with the basics. A truss is essentially a structural framework made up of interconnected triangles. These triangles are super strong because they distribute weight evenly across the entire structure. Think of it like a spiderweb – each strand works together to hold everything in place. Trusses are commonly used in roofs, bridges, and other large structures where strength and stability are key.

On the other hand, beams are horizontal structural elements designed to support loads. They’re like the strong arms of a building, holding everything up. Beams can be made from wood, steel, concrete, or even composite materials, depending on the project requirements. Together, trusses and beams form the backbone of many modern structures, ensuring they can handle whatever nature throws their way.

Why Are Truss and Beam So Important?

Here’s the thing – without truss and beam, most buildings would collapse under their own weight. These components provide the necessary support to keep structures standing tall and strong. Trusses, with their triangular design, are particularly effective at distributing loads, while beams handle the heavy lifting by bearing the weight of floors, roofs, and walls.

But it’s not just about strength. Truss and beam systems also offer flexibility in design. They allow architects and engineers to create open spaces, high ceilings, and unique shapes that would be impossible with traditional construction methods. Plus, they’re cost-effective, which is always a plus when you’re working on a budget.

Truss vs Beam: What’s the Difference?

While both truss and beam play essential roles in construction, they serve different purposes. Trusses are typically used for spanning large distances without needing additional support in the middle. This makes them perfect for roofs, bridges, and other structures where open space is important. Beams, on the other hand, are more versatile and can be used in a variety of applications, from supporting floors to holding up walls.

Another key difference is their shape. Trusses are made up of triangles, which makes them incredibly strong and stable. Beams, however, are usually straight and can be made from a variety of materials, depending on the project requirements. Both have their strengths and weaknesses, but when used together, they create a powerful combination that can handle just about anything.

Read also:Oprahs Favorite Cardigan The Ultimate Cozy Companion That Stole Our Hearts

Types of Trusses You Should Know About

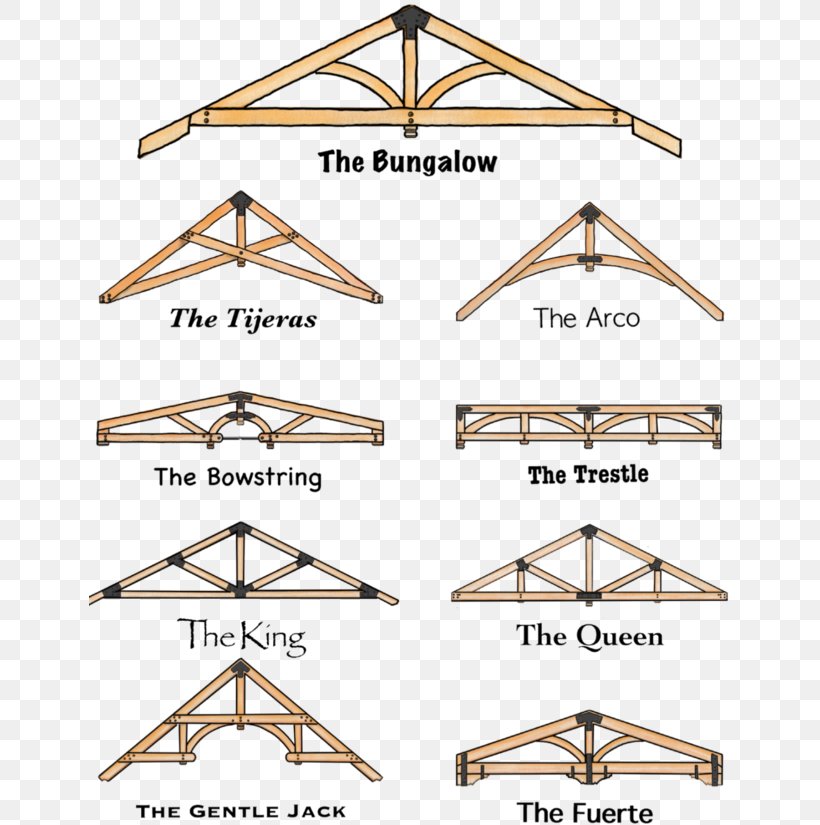

Now that we’ve covered the basics, let’s talk about the different types of trusses you might encounter. There are several varieties, each designed for specific applications. Here’s a quick rundown:

- King Post Truss: The simplest type of truss, consisting of two diagonal members and a vertical post. Great for small structures like sheds and garages.

- Queen Post Truss: Similar to the king post truss but with two vertical posts instead of one. Provides more support and is ideal for medium-sized structures.

- Pratt Truss: Uses diagonal members to create a more complex triangular pattern. Commonly used in bridges and large buildings.

- Warren Truss: Features alternating diagonal members that form a zigzag pattern. Offers excellent strength and is often used in roofs and bridges.

- Fink Truss: Also known as a "W" truss, this design uses multiple diagonal members to create a web-like pattern. Perfect for residential roofing.

Each type of truss has its own unique advantages and disadvantages, so choosing the right one depends on the specific needs of your project.

Understanding Beam Materials

When it comes to beams, the material you choose can make a big difference in performance. Here’s a look at some of the most common options:

Wood Beams

Wood is a classic choice for beams, especially in residential construction. It’s lightweight, easy to work with, and offers a natural aesthetic that many people love. However, wood beams can be prone to warping and rotting over time, so proper maintenance is essential.

Steel Beams

Steel beams are incredibly strong and durable, making them ideal for commercial and industrial applications. They can span long distances without sagging and are resistant to fire and pests. The downside? Steel is heavy and can be expensive, so it’s not always the best choice for smaller projects.

Concrete Beams

Concrete beams offer excellent load-bearing capacity and are often used in high-rise buildings and bridges. They’re fire-resistant and can last for decades with proper care. However, they’re not as flexible as wood or steel, so they’re not always the best choice for every situation.

Design Considerations for Truss and Beam Systems

Designing a truss and beam system isn’t as simple as throwing some materials together and hoping for the best. There are several factors to consider, including load capacity, span length, and material selection. Here’s what you need to keep in mind:

- Load Capacity: Make sure your truss and beam system can handle the weight it needs to support. This includes not only the structure itself but also any additional loads, like furniture, people, or snow.

- Span Length: The distance between supports is critical when designing trusses and beams. Longer spans require stronger materials and more complex designs.

- Material Selection: Choose materials based on their strength, durability, and cost. Don’t forget to consider factors like weather resistance and fire safety.

Working with a qualified engineer or architect can help ensure your truss and beam system is designed correctly and meets all necessary safety standards.

Common Challenges in Truss and Beam Construction

While truss and beam systems are incredibly effective, they’re not without their challenges. Here are some of the most common issues you might encounter:

Deflection

Deflection occurs when a beam bends under load. While some deflection is normal, excessive bending can compromise the structural integrity of a building. To prevent this, it’s important to use beams with sufficient strength and stiffness.

Vibration

Vibration can be a problem in truss and beam systems, especially in buildings with heavy foot traffic or machinery. To minimize vibration, engineers often use additional support members or damping materials.

Corrosion

Steel beams are particularly susceptible to corrosion if they’re exposed to moisture or chemicals. Regular maintenance and protective coatings can help extend their lifespan and prevent costly repairs down the road.

Cost Considerations for Truss and Beam Systems

Let’s talk money. Truss and beam systems can vary widely in cost depending on factors like material, size, and complexity. Here’s a breakdown of what you might expect to pay:

- Wood Trusses: Typically the most affordable option, wood trusses can cost anywhere from $1 to $3 per square foot.

- Steel Beams: Steel beams are more expensive, with prices ranging from $3 to $10 per linear foot, depending on size and grade.

- Concrete Beams: Concrete beams are on the pricier side, often costing $10 to $20 per linear foot or more.

Keep in mind that these are rough estimates and actual costs can vary based on location, labor rates, and project specifics. It’s always a good idea to get multiple quotes before making a final decision.

Installation Tips for Truss and Beam Systems

Installing truss and beam systems can be a challenging task, but with the right approach, it’s definitely doable. Here are some tips to help you get started:

- Plan Ahead: Before you begin installation, make sure you have a detailed plan in place. This should include measurements, material lists, and a timeline.

- Use Proper Tools: Investing in quality tools can make the installation process much smoother. From saws and drills to lifts and cranes, having the right equipment is essential.

- Follow Safety Protocols: Safety should always be your top priority. Wear appropriate gear, secure all equipment, and never take shortcuts that could put you or your team in danger.

Don’t hesitate to hire professionals if you’re unsure about any part of the installation process. It’s better to spend a little extra money upfront than risk damaging your structure or injuring yourself.

Maintenance and Longevity of Truss and Beam Systems

Like any structural component, truss and beam systems require regular maintenance to ensure they last as long as possible. Here’s how you can keep them in tip-top shape:

Regular Inspections

Performing regular inspections is key to catching potential problems before they become major issues. Look for signs of wear and tear, such as cracks, corrosion, or warping, and address them promptly.

Proper Cleaning

Keeping trusses and beams clean can help prevent damage from dirt, debris, and moisture. Use appropriate cleaning solutions and techniques based on the material of your components.

Protective Coatings

Applying protective coatings can extend the lifespan of your truss and beam system by shielding it from environmental factors like UV rays, rain, and snow. Make sure to follow manufacturer guidelines for application and maintenance.

Conclusion: Mastering Truss and Beam Systems

So there you have it – everything you need to know about truss and beam systems. From understanding the basics to tackling installation and maintenance, this guide has covered all the essential aspects of these crucial structural components. Remember, whether you’re building a small shed or designing a massive skyscraper, trusses and beams are the foundation of success.

Now it’s your turn. If you’ve found this article helpful, don’t forget to leave a comment or share it with your friends and colleagues. And if you’re ready to take the next step, check out our other resources on construction and engineering. Together, we can build a better future, one structure at a time.

Table of Contents

- What Exactly Are Truss and Beam?

- Why Are Truss and Beam So Important?

- Types of Trusses You Should Know About

- Understanding Beam Materials

- Design Considerations for Truss and Beam Systems

- Common Challenges in Truss and Beam Construction

- Cost Considerations for Truss and Beam Systems

- Installation Tips for Truss and Beam Systems

- Maintenance and Longevity of Truss and Beam Systems

- Conclusion: Mastering Truss and Beam Systems